- Contact Person : Ms. an jun

- Company Name : Botou Haide Machinery Manufacturing Co., Ltd.

- Tel : 86-317-8188885

- Fax : 86-317-8266866

- Address : Hebei,Botou,Fuzhuang Industry and development Zone

- Country/Region : China

- Zip : 062150

Rocek wool sandwich panel production line

TECHNICAL SCHEME

Introduction of consists component:

1. Coil mandrel and coil base frame , the un-coiled is passive

The quantity of coil mandrel is 4 , which could adapt for the inner diameter 500mm , the width is no more than 1300mm and weight is no more than 5000KGS , the outside diameter is no more than 1300mm .

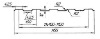

2. Roll forming machine

Roll forming machine: 18 steps, 8500mm*1520mm(length*width),the motor power is 5.5 KW.

Closing the roof side

3. One set of main body of the sandwich panel production line :

Specification: main Body: 15000mm*2200mm (length*width)

Up and bottom steel-panel machine 6000mm*2200mm(length*width)

Laminating machine 8000mm*2200mm (length*width)

The main driven motor power is 4KW.

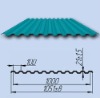

Microprofiler formed by the small rollers for wall panel !

4. Liquid glue mixing and scraping device for foaming

5. One set of cutting device :

Cutting machine can move longitudinally along product line;

Band saw of the cutting machine can move transversely,

Cutting machine moves longitudinally and transversely,

Cutting machine adopts one-side blade band saw manner,

There is panel tight-pressing system (pneumatic) in the cutting machine;

There is location limiter to limit longitudinal and transverse motion of cutting machine.The accuracy is ±2mm/1m.

6. One set of transferring rack:

Main transferring rack : 4000mm*1210mm(length*width),no driven power

7. Electrical control device :

The machine is controlled by PLC and touch screen

Technical parameter

1. Dimension : 48000*2400*2700mm

2. Forming speed: 3-6 m/min

3. Total power: 32kw

4. Weight : 16000kg

5. Control system: PLC control system full automatic control

6. Voltage : 380 v/3phase

7. Material thickness: 0.3-0.8mm

8. Plate material : color steel sheet

9. The feeding width of steel plate : 1250mm(roof)/1100mm(wall)

10. Sandwich thickness :50mm—250mm(can be adjusted)

11.Core material :Rock wool

12.User : roofs and walls

Ø Requirements for facilities

Needed place and workmen |

1.ground-level land |

2.≥5t overhead travelling crane |

3.≥-14°C temperature in the working department |

4.space for storing material |

5.space for laying the machine (about 50m*12m*7m) |

6.road for vehicle moving |

7.workmen:6-8 operator and porter |

Ø Sales term

Buyers should pay 30% of the total payment BY T/T in 7 days after signing <manufactured products purchase contract>. After finished production, we will inspect the machine and inform the buyer, the buyer send person to inspect goods, then payoff the whole payment before shipping out the goods. If the goods don’t accord with the standards, we will return all the advance payment.

Ø After sales service

This producing line is maintained for its whole life. For the first 18 months, we will replace broken parts free of charge. During the coming period, we will sell you spare parts at factory price. When the machine is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians travelling abroad.

Ø Delivery time

50 working days after receive the advance payment

Botou Haide Manchinery Manufacturing Co., Ltd

Rocek wool sandwich panel production line