- Contact Person : Ms. an jun

- Company Name : Botou Haide Machinery Manufacturing Co., Ltd.

- Tel : 86-317-8188885

- Fax : 86-317-8266866

- Address : Hebei,Botou,Fuzhuang Industry and development Zone

- Country/Region : China

- Zip : 062150

Sandwich panel production line

Sandwich panel production line

EPS panel

Rockwool panel

Sandwich panel production line

Instroduction

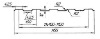

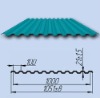

SLF sandwich panel production line is main equipment that is used to produce sandwich panel a new building materials which has the features as stable .light .solidity and besutiful appearance.The application of sandwich panels in varilus usage of large-scale house like supermarket ,workshop ,warehouse is convenient and fast in building .Then also can be offered to construct refrigerator .clearing room .etc .

Feature

This line adopts advanced technique,which integrates gas ,electricity and machinery ,and this line is the special equipment for processing colorrd steel sandwich panel .its working speed can be adjusted by frequency converter,and it can process sandwich panel at one time .

The line for sandwich panel is made up of a sandwich panel laminating system and roll forming machine .Both the laminating system and roll forming machine can work independently .The roll forming machine of the line consists of feeding equipment .roll forming section.while the laminating system is made up of such equipment as decoiler ,feeding ,squeezing ,heating ,laminating ,edge rolling ,edge turn-over ,groove-making ,edge pruning ,pneumatic device ,automatic cutting and control system .The whole machine possesses advanced working crafts .

The sandwich panels of this line are widely used as the roof and wall of factory ,warehouse ,garage ,exhibition center, cinema ,theatre ,gymnasium,civil construction ,stadium ,cold storage ,etc .

1)Corrugated Sandwich Panels can be produced directly, without the shortcoming that traditional corrugated sandwich panels have to be laminated manually after the forming of corrugated sheet.

2)Both the roll forming machine and the laminating system can work independently.

3)Beautiful appearance, Low noise, High efficiency

4)The line employs advanced PLC and sets the panel length and cuts the panel automatically.

Technical parameter

1. Installation dimension of machine: 36m*3.6m*2.4m

2. Forming speed: 0-4m/min

3. Main motor power: 32kw

4. Total weight : 14T

5. Control system: PLC control system full automatic control

6. Voltage : 380 v/5phase

7.Annual production of this line (eight ours a day )is about 600000 square meters .

8 .Delivery time : 45 working days after received advanced payment

9. the thickness of upper steel plate: 0.286-0.6mm

10. the feeding width of steel plate :1000/1200mm

11 the effective width :980 mm

12Coil inner diameter:500mm, 600mm coil weight: 3000-5000kg

13. EPS core material the thickness: 47-247mm

14 material :EPS rockwool

15workshop size :48*10*5

Sandwich panel production line